Artificial Intelligence

Modeling of Agile MicroFactory System using Unified Modeling Language

As the world is shedding the light on best utilization of resources, microfactory has been identified as the next big move in manufacturing. The microfactory is a small-to-medium factory that utilizes limited resources to produce flexible small batch size products. Microfactory is considered a complex agile system with integrated system components and interactions that aim to accomplish flexibility in production volume while best utilizing limited resources. Thus, modeling the microfactory considering these factors is of critical importance. The Unified Modeling Language (UML) is an effective

Lab to Industry

In terms of environmental and socio-economic benefits, the utilization of agro-fiber wastes in pulp-based product manufacturing is advantageous. Non-wood plant pulp production has shattered, and numerous non-wood fiber resources are being commercially used to make chemical pulp and paper in China, India, Latin America, Africa, the Middle East, and Turkey. Agricultural wastes, including rice and wheat straws, sorghum stalks, and annual plants like hemp and jute, are being utilized as raw materials for pulp and paper manufacture. In addition, various research has been carried out to introduce

Technological innovation in ergonomics & safety in automotive industries in Egypt

The increase in the complexity and the inspiring environment between the automotive organizations in Egypt forced the quality experts and management team to propose various tools related to Quality Management Systems but there is a slight apprehension to the ergonomic concepts in these industries. This study investigates the complications related to the ergonomics in the assembly line of an automotive company in Egypt. The assembly line is divided into several stations including trim line, chassis line and a glass handling station. The focus of this study is the ergonomics of the glass

Analysis of musculoskeletal disorders in personal care industries in Egypt

The increase in the complexity of operations in personal care industries in Egypt forced the ergonomic experts to propose various tools to analyze the human errors and eliminate the most dangerous operations according to the international standards of safety and ergonomics. International references such as the Rapid Upper Limb Assessment (RULA) and Rapid Entire Body Assessment (REBA) analysis are performed to investigate different postures as well as Computer Aided Three-Dimensional Interactive Application (CATIA) and Maynard Operation Sequence Technique (MOST softwares). A modified scissor

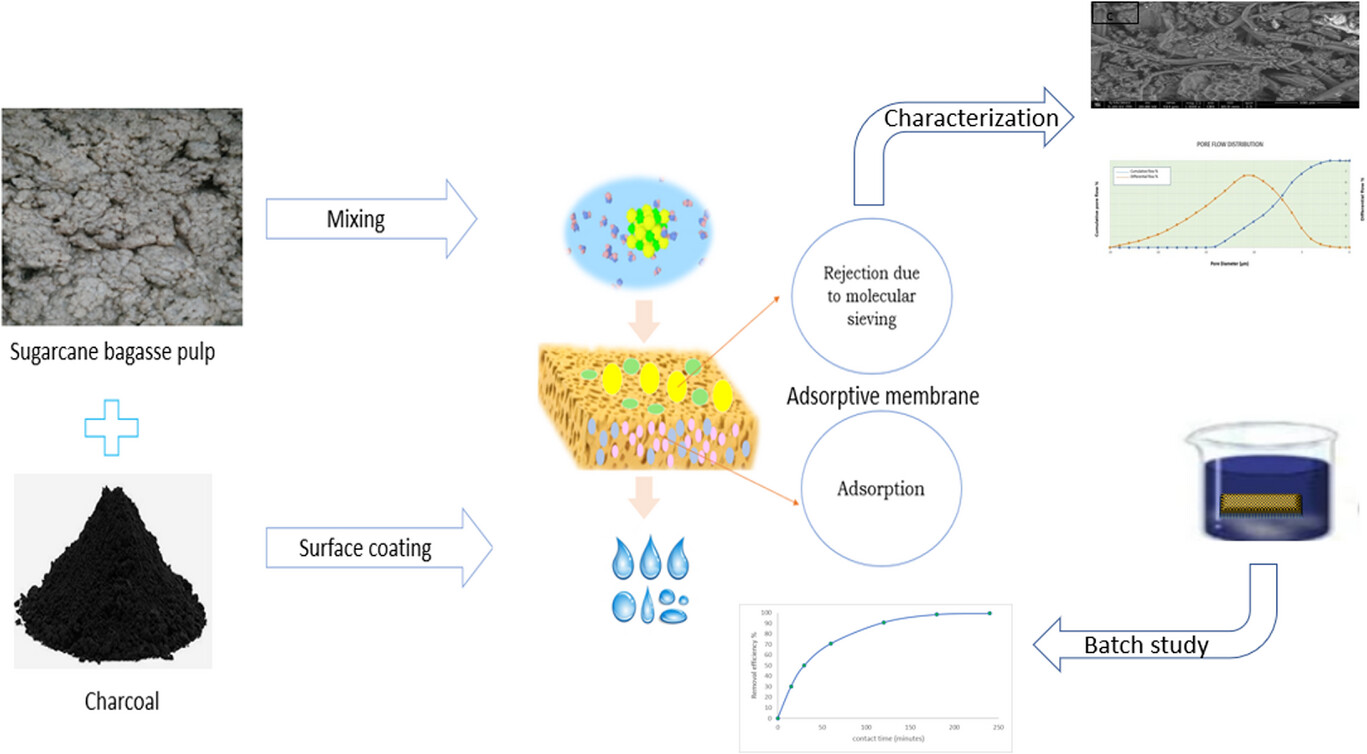

Methylene Blue Removal on Biodegradable Adsorptive Membranes Fabricated From Sugarcane Bagasse Pulp: Characterization and Performance Study

Dye-containing waste should be carefully treated using environmentally friendly technology to prevent environmental harm and preserve water resources. Adsorptive membranes are a promising new approach for decreasing, recovering, and reusing waste while also removing contaminants like dyes. In this work, two different techniques are employed to create membranes using sugarcane bagasse pulp and carbon from charcoal. In the first technique, the surface of sugarcane bagasse is coated with charcoal paste as shown in Figure 1, while in the second, the carbon is combined with sugarcane bagasse pulp

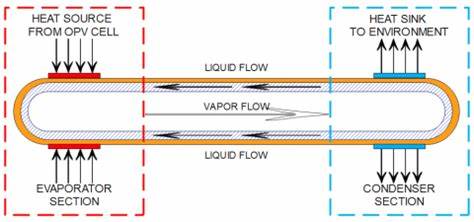

Improving the Performance of Organic Photovoltaic Panels by Integrating Heat Pipe for Cooling

A new photovoltaic technology is manufactured from an organic material that easily degrades in nature. Unfortunately, organic photovoltaics suffer from low thermal stability and lower power conversion efficiency compared with silicon-based photovoltaics. Cooling is critical in this type of photovoltaic because of these factors. This research investigates a new method to cool this organic photovoltaic with a heat pipe to achieve a minimum operating temperature and maximum temperature uniformity, the heat pipe design is fixed, and the number of cells served by a single heat pipe is studied. For

Finite Element Analysis and Experimental Study of Manufacturing Thin-Walled Five-Branched AISI 304 Stainless Steel Tubes with Different Diameters Using a Hydroforming Process

This study aims to investigate the feasibility of hydroforming (HF) technology coupled with response surface optimization for producing high-quality five-branched AISI 304 stainless steel tubes with different diameters, addressing the shortcomings of traditional manufacturing processes. Conventional techniques often result in issues with multiple consumables, low precision, and subpar performance. The research focuses on finding optimal forming parameters for a more effective process. Initial attempts at a five-branched tube proved unfeasible. Instead, a multi-step forming approach was adopted

Towards a circular economy: valorization of banana peels by developing bio-composites thermal insulators

The building construction materials are responsible for a large amount of energy and natural resource consumption. In light of the current challenges of resource scarcity and global climate change, the circular economy (CE) is a promising strategy to mitigate pressure on the environment, improve supplying of raw materials, and increase new market and employment opportunities. Developing eco-friendly thermal insulation materials based on agro-waste is a new waste management trend to achieve the sustainability of the resource and energy consumption in the construction sectors. In this work

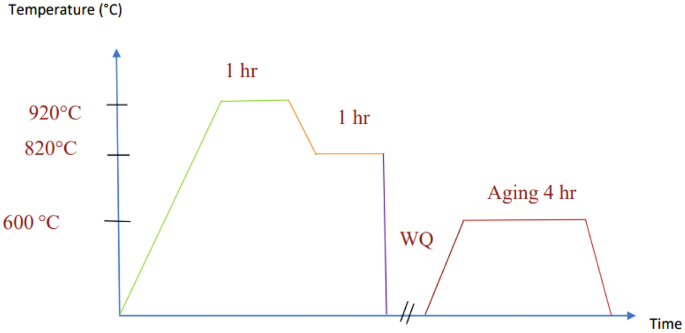

Optimization of machining parameters for turning operation of heat-treated Ti-6Al-3Mo-2Nb-2Sn-2Zr-1.5Cr alloy by Taguchi method

TC21 alloy is a high-strength titanium alloy that has been gaining attention in various industries for its excellent combination of strength, toughness, and corrosion resistance. Given that this alloy is hard to cut material, therefore this study aims to optimize the process parameters of Turing this alloy under different conditions (i.e. as-received alloy, and heat-treated alloy). The L9 Taguchi approach-base orthogonal array is used to determine the optimum cutting parameters and the least number of experimental trials required. The achievement of this target, three different cutting

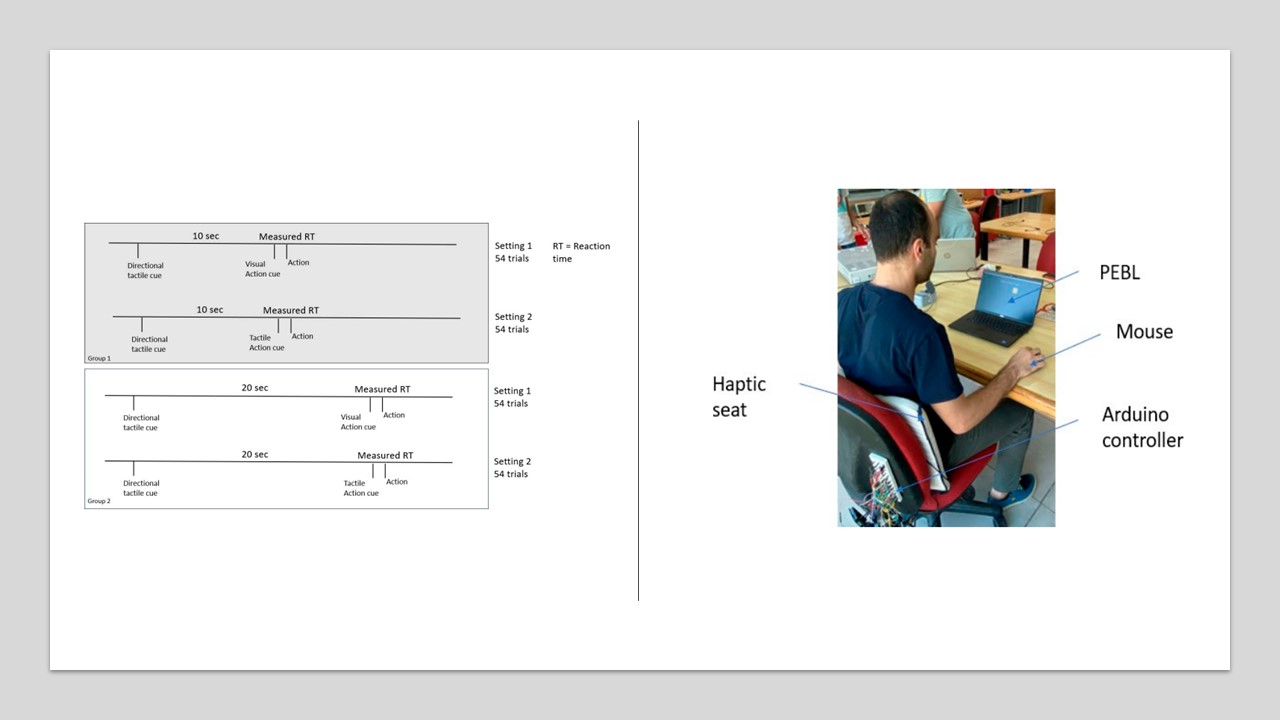

The Effect of Directional Tactile Memory of the Back of the User on Reaction Time and Accuracy

Tactile memory is the cognitive process of storing and recalling information that has been perceived through the sense of touch. Directional tactile memory involves the encoding and retrieval of sensory data associated with a tactile experience, allowing individuals to remember and recognize directional information encoded through the sense of touch. A new method for providing directional tactile feedback, at the back of the user, has been developed to investigate the efficacy of directional tactile memory, its decay over time, and its impact during a concurrent cognitive task. Two experiments